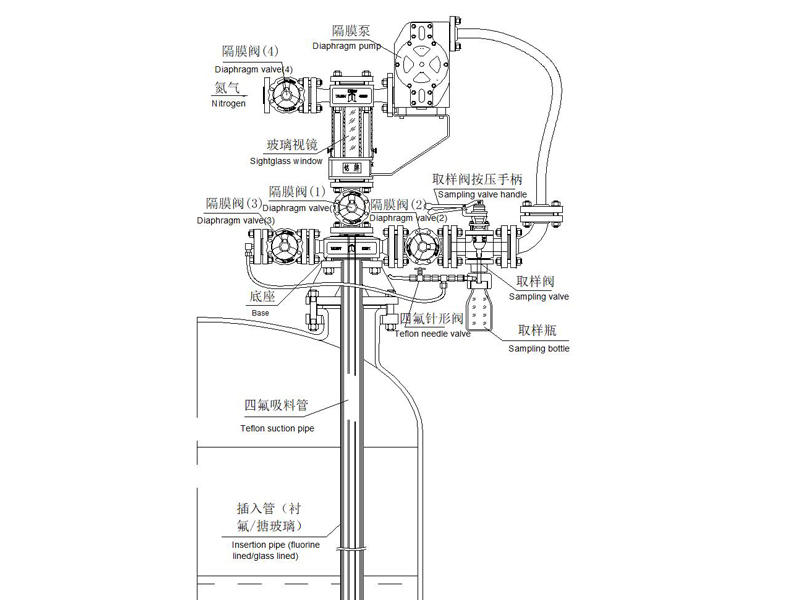

此系统为防腐在线取样装置。取样物料接触各部件均采用里衬PFA、衬氟材质,达到防腐目的,四氟吸料管配套插入管(衬氟/搪玻璃材质)浸于釜内料液以下,增加其过程的稳定性。隔膜泵以洁净庄缩空气为动力,物料在取样系统中形成闭环循环回路,过程快捷、安全、无污染。

This system is on-line anti-corrosive sampling device. The part in contact with medium is lined with PFA or Fluorine to achieve the purpose of anti-corrosion. The Teflon suction pipe matched with the insertion pipe (fluorine lined / glass lined) is immersed below the medium liquid in the vessel to increase the stability of the process. The diaphragm pump is powered by clean compressed air and the sample flows in a closed circulation loop in the sampling system, which is fast, safe and pollution-free.

取样器安装及取样步骤: Sample Installation and Sampling Steps

安装步骤:

Installation procedure

1.将(插入管)安装到反应盆相应管口上,紧固螺栓。

Install (the insertion pipe} on the corresponding nozzle of the reactor and fasten the bolts

2.将取样系统下端(底座)与(隔膜阀1)拆分,将(底座)安装到(插入管)上端。

Separate the lower end (base) of the sampling system from (diaphragm valve 1), and install (base) to the upper end of (insertion pipe)

3.将四氟外翻边(吸料管)装入(底座)内腔,四氟(吸料管)外翻边处于(阀座)密封面处吻合。

Put the Teflon outer flanging(suction pipe) into the inner cavity of the (base), and the Teflon outer flange of (the suction pipe) is matched at the sealing surface of the (valve seat)

4.将其余取样系统主体与其连接紧固,保证(底座)密封处压紧、无泄漏。

Connect and tighten the rest of the sampling system body to ensure that the sealing part of (base} is tight and without leakage.

取样步骤:

Sampling procedure

1开机前确认、检查:Confirm and check before starting

a:所有隔膜阀处于关闭状态。

All diaphragm valves are closed

b:取样系统内、外无残余物,视镜无破损。

There is no residue inside and outside the sampling system, and no damage to the sightglass

b:隔膜泵用0.2~0.3 MPa洁净气源。

File the diaphragm pump with 0.2~0.3 MPa clean air pressure.

c:反吹用0.2~0.3 MPa氮气气源。

0.2~0.3 MPa nitrogen gas source is used for back blowing

d:备用150/250ml硼硅玻璃取样瓶1支。

One spare 150/250 ml borosilicate glass sampling bottle is needed

2.循环回路: Circulation Loop:

a:打开(阀门1)——打开(阀门2)。

Open (valve 1) -- open (valve 2)

b:打开(隔膜泵)。泵工作运转。

Open (diaphragm pump). The pump works

c:观察(视镜)。窗口内充满物料,同时形成取样循环回路状态。

Observe (sightglass).The window is filled with medium, and a sampling ciculation loop state is formed at the same time.

3.取样:Sampling

a:按压(取样阀手柄)。观察取样瓶量剂,适时松开取样阀手柄。

Press (sampling valve handle) Observe the dosage of the sampling bottle and release the handle of the sampling valve in time.

b:关闭(隔膜泵)。Turn off (diaphragm pump).

c:取样瓶内排气过程。

The exhausting process in the sampling bottle.

c1:当罐内常压时打开(隔膜阀3)-关闭 (隔膜阀3)。

When the tank is with atmospheric pressure: open (diaphragm valve 3) - close (diaphragm valve 3).

c2:当罐内≤0.2MPa时:打开(四氟针型阀)-关闭(四氟针型阀)。

When the pressure in the tank is less than or equal to 0.2MPa open (Teflon needle valve) - close (Teflon needle valve).

注 引导排出有害气体到安全存贮装置中。

Note: discharge the harmful gases to a safe storage device.

d:取下(取样瓶)密封瓶口----装入(备用取祥瓶)。

Remove the (sampling bottle) and seal the bottle mouth - put in (spare sampling bottle).

e:打开(隔膜阀4)----打开(氮气)将系统内残余物料反吹盆内——关闭(隔膜阀4)。

Open (diaphragm valve 4) - make (nitrogen) to blow the residual medium in the system back into the vessel - close (d闭 phragm valve 4).

f:关闭(隔膜阀2)----关闭(隔膜阀1)。

Close (diaphragm Valve 2) - Close (diaphragm Valve 1)

g:取样结束。

Sampling complete.

反应釜带自动取样系统清洗过程说明: DescrlptIon of the C|eanlng Pocess of the Reactor with Aut omatic Samphng System:

在进行整个反应釜的清洗过程中,可以按照以上取样步骤描述进行取样系统内部清洗、 吹扫。

During the cleaning process of the whole reacto,the internal cleaning and purging of the sampling system can be car ied out according to the above sampling steps.